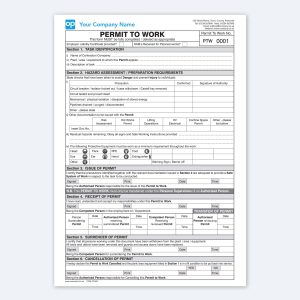

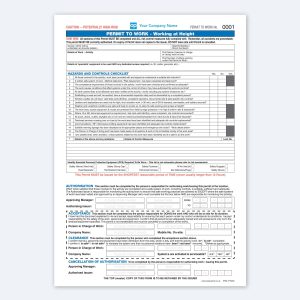

Permit to Work

Ensure a safe work environment and regulatory compliance with personalised forms.

Can't find what you're looking for?

Permit to Work

Health and safety permits to work are crucial because they serve as formal, documented procedures for managing high-risk activities in the workplace.

These permits help ensure that specific safety measures and precautions are in place before potentially hazardous tasks are undertaken, reducing the risk of accidents, injuries, and environmental harm.

They provide a structured framework for communication, coordination, and accountability, ensuring that everyone involved in a task is aware of the associated risks and knows how to mitigate them.

By requiring permits for tasks such as confined space entry, hot work, or electrical maintenance, organisations prioritise the well-being of their employees and the protection of their assets, fostering a safer work environment and regulatory compliance.

Permits to Work are essential tools in maintaining safety standards across diverse industries. They serve as a critical component of a company’s safety management system and are crucial for preventing accidents and protecting both employees and the environment. Let’s delve further into the various aspects of permits to work.

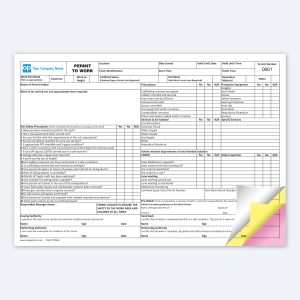

Types of Permits to Work:

Permits to Work are not one-size-fits-all documents. Instead, they come in various types tailored to specific tasks or industries. Some common types include:

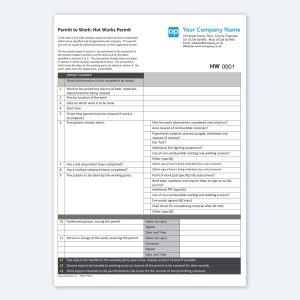

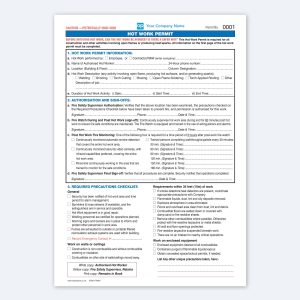

- Hot Work Permit: For activities involving open flames, welding, or cutting, as they carry a high risk of fire.

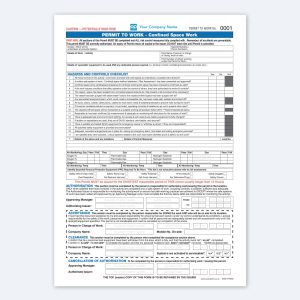

- Confined Space Entry Permit: Required for tasks inside confined spaces, which can be life-threatening due to limited access and ventilation.

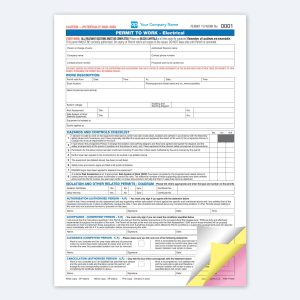

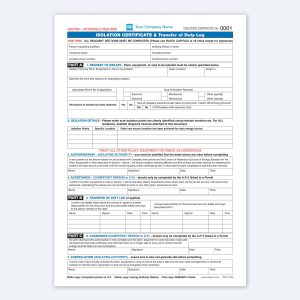

- Electrical Work Permit: Necessary for electrical maintenance and repair tasks, as electrocution hazards are prevalent.

- Working at Heights Permit: For tasks where employees are exposed to the risk of falling, such as construction or maintenance on elevated platforms.

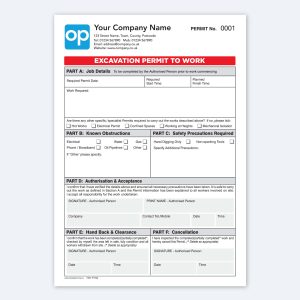

- Excavation Permit: Pertinent when digging, trenching, or excavation work is involved, as it can lead to collapses or cave-ins.

- Chemical or Hazardous Material Work Permit: For tasks involving handling or processing dangerous chemicals, ensuring proper safety measures are taken.

The Permit to Work Process:

The process of issuing and using permits to work involves several key steps:

- Request: The first step is the request for a permit, typically initiated by the employee or contractor who intends to carry out the work. The request outlines the type of work, location, and expected duration.

- Risk Assessment: A thorough risk assessment is conducted to identify potential hazards and determine the necessary safety measures. This includes assessing the equipment, environment, and any potential impact on nearby activities.

- Authorisation: Once the risks are assessed and mitigated, the permit is reviewed and authorized by designated personnel. This often includes safety officers, supervisors, and, in some cases, higher management.

- Communication: All relevant parties are informed about the approved permit, including the worker(s) involved and anyone who may be affected by the work, to ensure everyone is aware of the ongoing activity and potential risks.

- Work Execution: The work is then carried out following the stipulated safety guidelines and time frame. Workers must adhere strictly to the conditions outlined in the permit.

- Monitoring and Compliance: Safety officers and supervisors typically oversee the work, ensuring that safety measures are being followed. Any deviation or changes in the work plan should be promptly communicated and authorized.

- Closure and Review: Once the work is completed, the permit is closed. A review is conducted to assess the effectiveness of safety measures and to learn from the experience, making any necessary adjustments for future work.

- Benefits of Permits to Work:

Permits to Work offer several advantages:

- Accident Prevention: Their primary purpose is to prevent accidents by ensuring that only qualified individuals undertake specific tasks while following established safety protocols.

- Accountability: The permits establish accountability by designating responsible personnel for the safety of the work, reducing the likelihood of negligence.

- Documentation: They provide a documented record of safety measures, risk assessments, and compliance, which can be crucial in case of investigations or legal proceedings.

- Continuous Improvement: The review process at the end of a permit’s validity allows companies to continuously improve safety procedures and identify areas that need enhancement.

Challenges and Considerations:

Despite their many benefits, permits to work can sometimes be seen as bureaucratic or time-consuming. Striking the right balance between safety and efficiency is essential. Training and communication play a vital role in making sure that all employees understand the importance of permits and are willing to comply with the process.

In conclusion, Permits to Work are indispensable tools in managing safety across various industries. They offer a structured approach to risk assessment and mitigation, fostering a culture of safety and accountability. By ensuring that only trained and authorised individuals perform hazardous tasks, permits to work contribute to reducing accidents and protecting both human lives and the environment. However, it’s essential for organisations to balance safety with efficiency and foster a culture of safety compliance among their employees.

Trusted Supplier to UK Businesses

Expert Customer Service

Quality Guaranteed