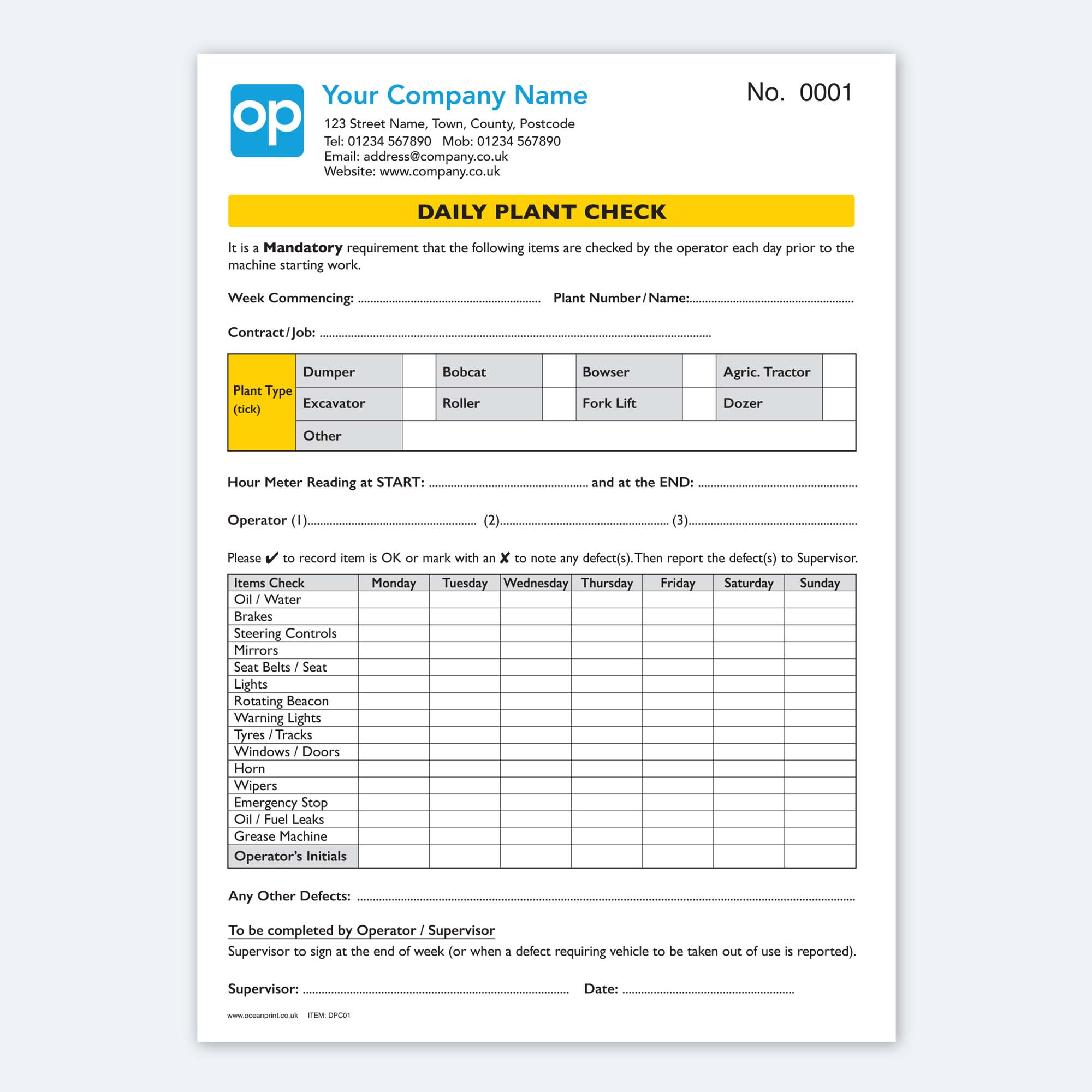

Daily Plant Inspection Checklist

£0.74 – £75.00 ex. VAT

ITEM: DPC01

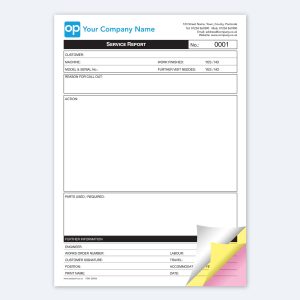

Personalised Service Report pads offer a tailored and professional way to document service details efficiently.

Key features of the form:

- Week commencing

- Plant Number / Name

- Contract / Job

- Plant type

- Meter reading

- Checklist and days of week

- Note any other defects

- Sign off by Operator / Supervisor

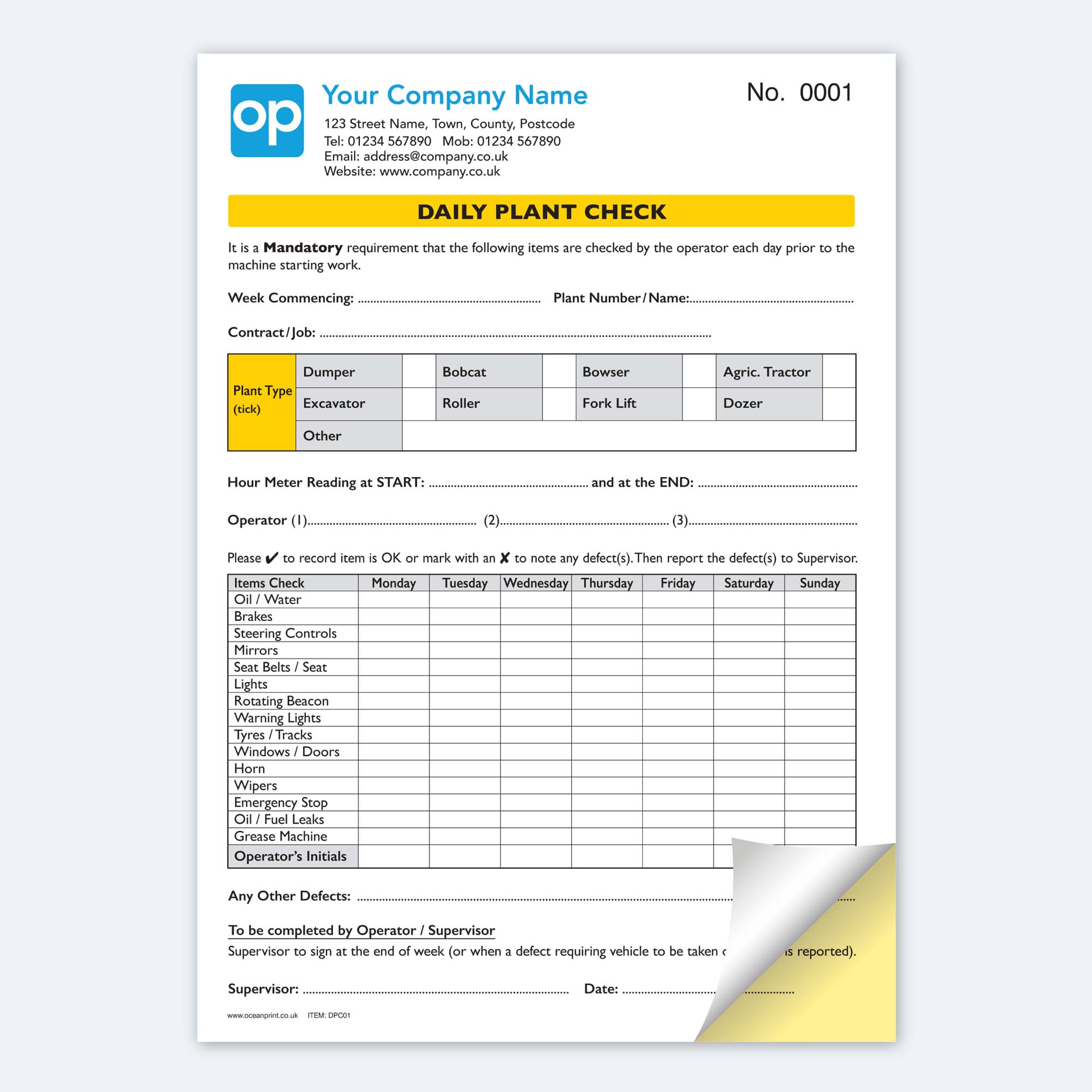

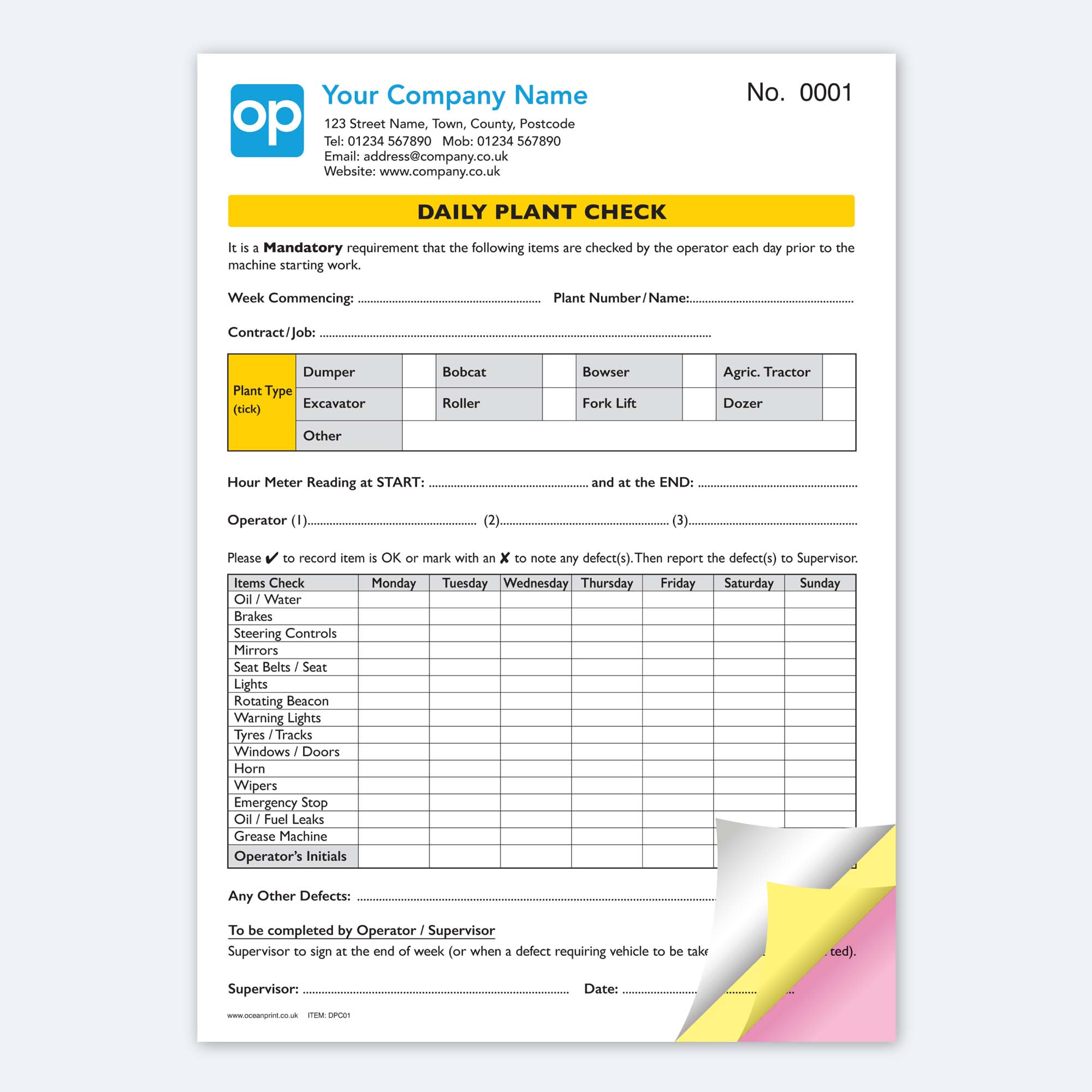

Product features: Personalised with your company branding | A4 210mm x 297mm | Single colour or full colour | Available in duplicate or triplicate carbonless NCR | Sequential numbering (optional) | 50 sets in every pad and book | Pads, books or glued loose sets | Writing shield with every NCR pad and book

Ready to personalise? Once your order is placed our Studio Team can personalise the Daily Plant Inspection Checklist by adding your company branding. The Studio Team can adjust other parts of the template to suit your requirements – just let them know in the notes when placing the order. You’ll receive a PDF proof for approval before printing commences.

Order Daily Plant Inspection Checklist

Daily Plant Inspection Checklist

A Daily Plant Inspection Checklist is a document or form used in industrial and manufacturing settings to ensure that machinery and equipment are in proper working condition and safe for operation on a daily basis. The purpose of this checklist is to systematically assess and record the condition of various components including:

1. Machinery and Equipment: Check for signs of wear and tear, damage, or malfunctions in machines, tools, and equipment.

2. Safety Features: Ensure that safety features such as emergency stop buttons, safety guards, and interlocks are functioning correctly.

3. Electrical Systems: Inspect electrical wiring, connections, and components for any issues like exposed wires or electrical hazards.

4. Fluid Systems: Check for leaks, pressure levels, and proper functioning of hydraulic, pneumatic, or other fluid systems.

A Daily Plant Inspection Checklist helps identify potential safety hazards, equipment problems, or maintenance needs early, reducing the risk of accidents, downtime, and costly repairs. It also promotes a culture of safety and accountability within the organisation. These checklists may vary depending on the specific industry, facility, and machinery in use, and they should be customised to address the unique needs and risks of each plant. Regular use of these checklists is a vital part of ensuring workplace safety and compliance with relevant regulations.

Trusted Supplier to UK Businesses

Expert Customer Service

Quality Guaranteed